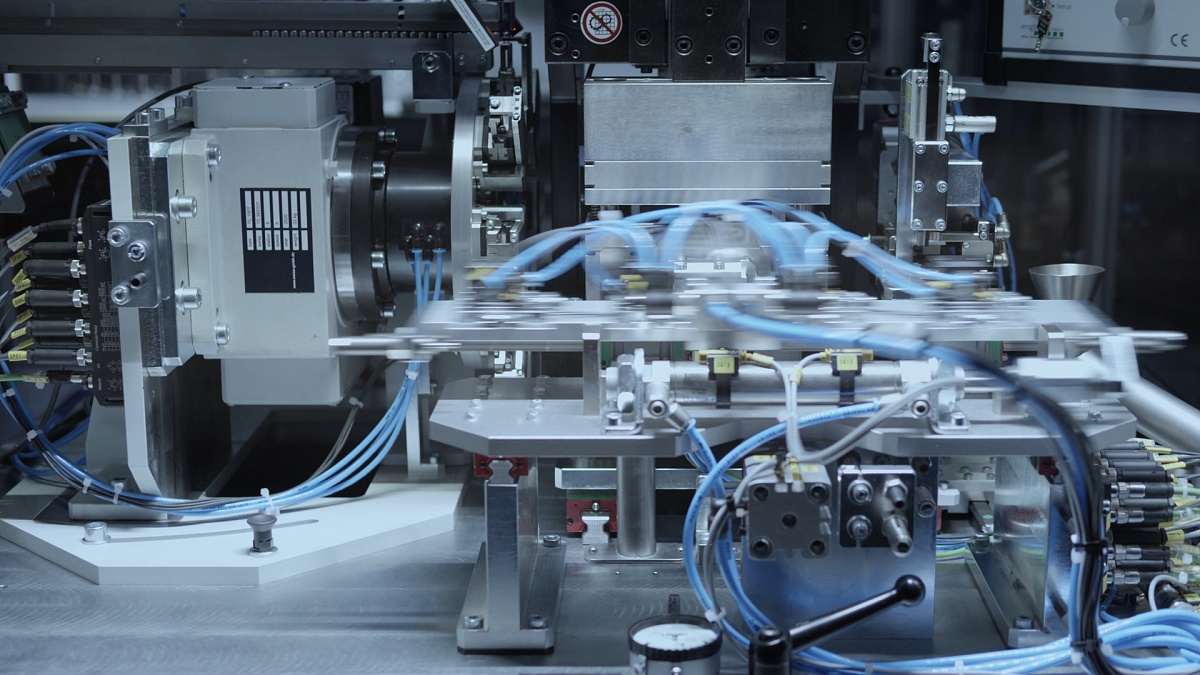

Linear transfer assembly systems are primarily designated for independent production lines and are composed of transport units from various suppliers. The speed of the production pallet and its indexed work position is modularly implemented in each system design. Furthermore, the systems enable the division or integration of production pallets on parallel transport branches, and can incorporate revolving or multilevel movement. There is no restriction to the length or number of stations within the production line. The modular arrangement of the system allows the design of the dispositional layout of the line according to the space specified by the customer.

Linear transfer assembly systems are extremely modular as regards the positioning of the individual assembly positions in the line. The design takes into account the input of the material, the size of the assembly units and servicing access. Furthermore, more operating points can be integrated into the line in these systems without affecting the work cycle. These systems are primarily designated for large-volume serial production. The working cycle of systems of this design can be as high as 35 pieces per minute in combination with automatic feeders.

Manually operated systems are designed with maximum respect towards workplace ergonomics and material input. The systems thus designed fulfil the strictest requirements for checking assembly processes which are implemented either through construction measures or monitoring systems. We offer our customers such systems in the form of remote monitoring of operation and traceability systems for reverse tracking of a specific product.