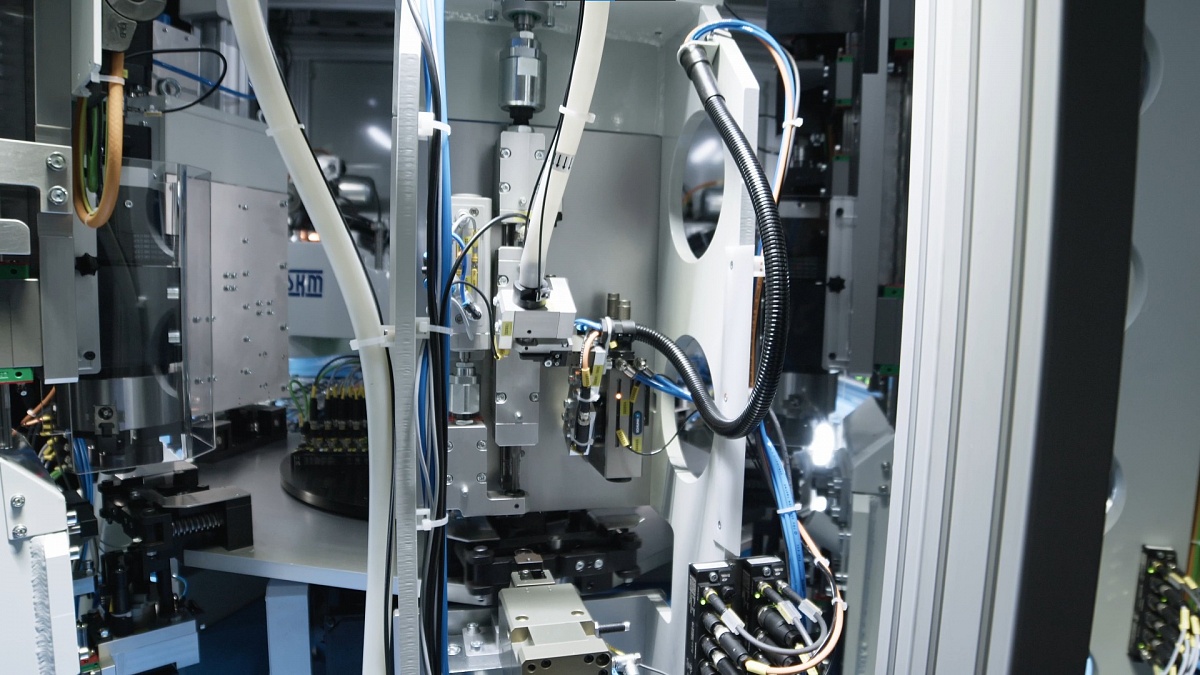

Rotary transfer assembly systems are used as independent production machines or can be integrated into production lines. Rotary transfer assembly systems utilize revolving tables with a set number of positions. Revolving and indexing of the table is carried out by a mechanical cam. In this manner rapid and precise movement between individual production points can be achieved. The maximum number of positions is determined by the number of divisions and by service access to the individual stations.

Rotary transfer assembly systems are designated for low volume and high volume production. The production cycle of such systems can be up to 35 pieces per minute and are fed either automatically by a feeder or manually by an operator.

The design of manually operated assembly systems is carried out with respect to the ergonomics of the workplace and the supply of the material to be processed. Such systems fulfil the strictest requirements for checking systems of assembly processes which are implemented either through construction measures or monitoring systems. We offer our customers such systems in the form of remote monitoring of operation and traceability systems for reverse tracking of a specific product.